Condition Monitoring +

Industrial IoT Platform

Sensor & AI powered

Leverage real-time machine data and smart sensors to monitor performance, anomaly detection and improve uptimes.

Open Machine Platform

We are an open machine data platform designed for today’s demanding companies that thrive on machine efficiency.

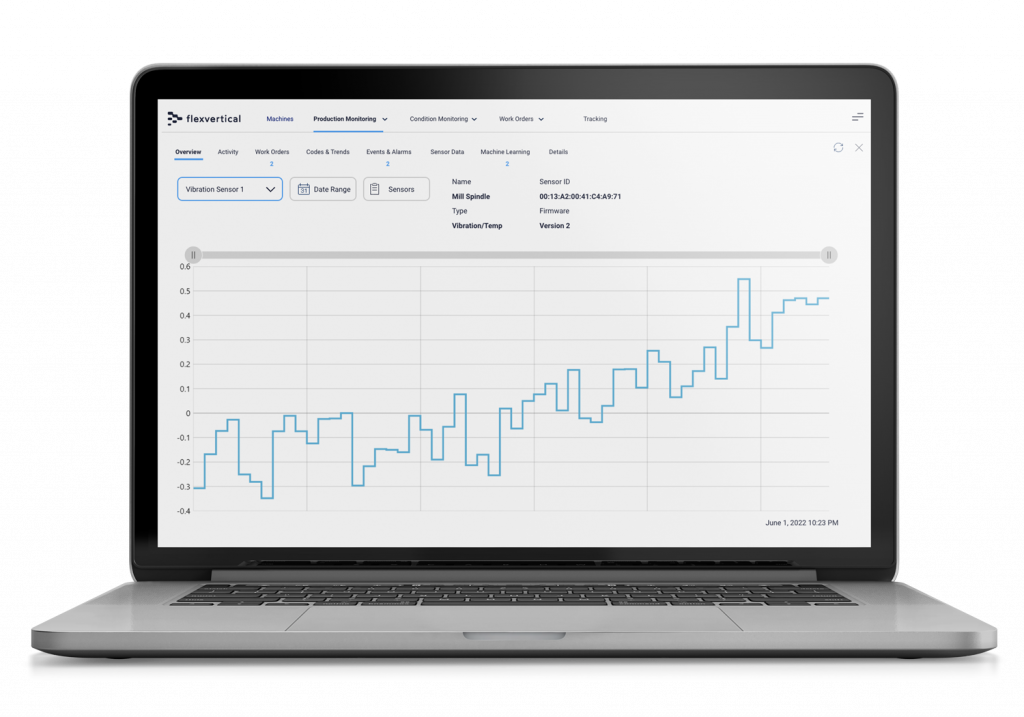

Monitor

Performance

Gain visibility into machine performance metrics and

sensor data all while reducing downtime.

Powered by Machine Learning

Use machine learning to process sensor data and detect machine performance anomalies and events.

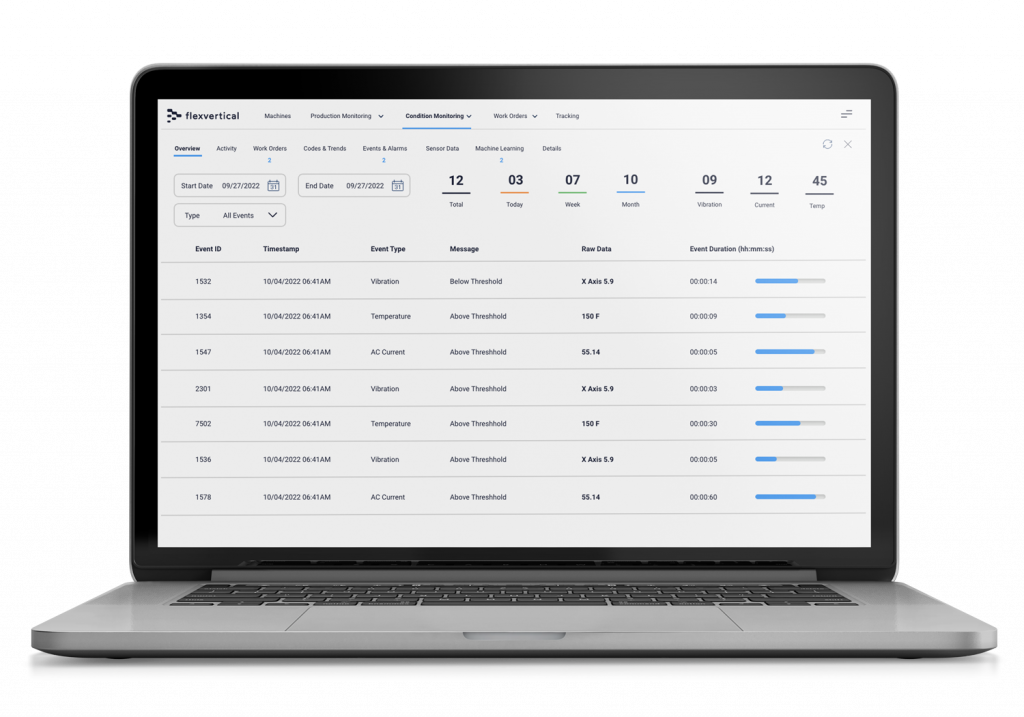

Event Driven Notifications

Receive real-time notifications that are driven by events and anomalies detected within your machine data.

IoT Sensor

Ready

Support for today’s major IoT sensors that are MQTT protocol compatible. Vibration, temperature, humidity, CO2, AC current come standard.

Edge I/O &

PLC Ready

Collect and exchange on-premises OT/PLC data via Ignition, OPC UA, MQTT. Support for I/O such as analog, discrete, switches and relays.

Stand-alone Data Connectivity

Our out-of-the-box cellular gateway provides seamless data connectivity to our platform. No IT support or integration required.

Machine Health

Measure a machine’s health by analyzing sensor and activity data to identify and resolve potential failures or performance degradation.

Machine Utilization

Accurately measure a machine’s utilization rate, downtime statistics, and operational readiness.

Performance Trends

Query real-time and historical machine data to identify underlying performance trends and root cause indicators.

Automatic Workflows

Eliminate manual processes by leveraging real-time machine data and events to create automatic workflows such as smart maintenance work orders.

Preventative Maintenance

Configure smart workflows that generate maintenance actions driven by machine utilization parameters, alarms, events, and calendar-based scheduling.

Events & Notifications

Receive critical email and text notifications for all monitoring machines and equipment. Configure notifications based on users, groups and shifts.

Integrated ML Solution

Our machine learning module is integrated within our software platform without the need to install additional software or plug-ins. *No additional cost to customers.

Dynamic Data

Trainer

Configure the data trainer to retrieve machine data at scheduled intervals for the re-training of the anomaly detection engine.

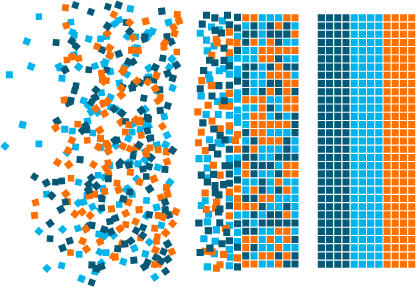

Anomaly

Detection

Leveraging popular machine learning models such as HBOS, KNN and LOF; the anomaly detection engine identifies sensor data anomalies to trigger intelligent workflows.

Flexible Data

Model

Open data model structure to process multiple type of machine sensor data payloads regardless of hardware manufacturer or data source.